Professional Analysis: Process Deconstruction and Industrial Code of Precision Replica Watches

The core value of industrialized precision manufacturing together with craftsmanship represents the fundamental concept of mechanical watches. This paper examines the manufacturing techniques of high-end replica watches by analyzing three aspects: parts, movements, and assembly processes to evaluate the technical limitations of industrializing handmade techniques during the modern era.

I. Material Science: Metallurgical Development from 316L to 904L.

The skeleton elements of contemporary fashion watches have developed into standardized parts that follow a systematic structure.

316L steel: Basic models use this material because it provides enough wear resistance for daily use along with a hardness rating between HRC 25-30 and requires PVD coating to achieve mirror polishing.

904L steel: stands as a proprietary material of Rolex and other brands which has increased its nickel-chromium content to 23%/20% while enhancing anti-sensitivity by 300% compared to 316L and resulting in a glass polish level above 98° but increasing tool wear by 40%.

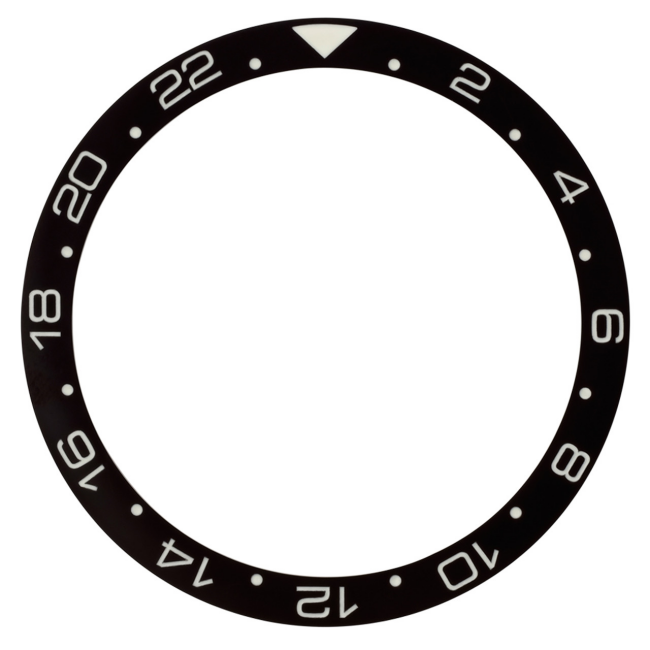

The manufacturing of ceramic bezels utilizes ZrO2 (coke oxidation) high temperature sintering to produce Mohs hardness of 8.5 while laser polishing requires maintaining a depth precision of 0.15mm±0.02mm on the pallet belt.

Technical breakthrough.

Swiss STUDER S33 CNC lathes perform high-precision operations at 0.001mm accuracy levels yet the sticking behavior of 904L steel requires technical expertise to adjust cutting parameters which presents a significant hurdle for counterfeiting technology.

Second, movement architecture: Swiss ETA and Asian customization game.

1. Swiss movement.

ETA 2824-2: 28,800 vibration frequency, 38 hours of power reserve, 127 parts, 4.6mm thickness.

ETA 2892-A2 has an ultra-thin profile of 3.6mm which leads to enhanced end point automatic winding efficiency reaching 82%.

The difficulty in reproducing this movement stems from the Rockwell hardness treatment of the barrel spring reaching HRC 52-54 and the precise grinding requirement for the escape wheel shaft tip diameter at 0.08mm.

2. Asian movement.

The Seagull ST2130 operates at a frequency deviation of ±5 seconds/day when compared to ETA 2824.

Dandong 4130 features a Titanium movement with an interlocking clearance of 0.03mm between its column wheel and vertical clutch structure.

Laser processing enables cost reduction for single movement manufacturing by 60% through its replacement of traditional hollow patterns.

III. Assembly process: Micrometer war under the microscope.

1. Hand system.

The hole diameter tolerance of second hand shafts should be maintained at or below 0.005mm.

The luminous filling material Super-LumiNova C3 has a 0.12mm coating thickness which contracts at a rate of 2.7% after curing.

2. Waterproof structure.

The screw-in crown features threads with a 0.35mm pitch and a 0.6N·m tightening torque.

A pneumatic air valve operates automatically under a 3ATM pressure difference to trigger pressure relief and the precision spring requires 72 hours of aging to achieve proper elastic coefficient performance.

3. Surface treatment.

A 1200 mesh tungsten steel grinding wheel processes the wire drawing operation at 15cm/min speed.

The electroplating layer measures 2μm thick and requires a consistent current density of 1.2A/dm² during the process.

Fourth, the ethical dilemma of industrialized production.

The current market contains two distinct product lines:

Regular replicas: The original movement architecture serves as a foundation for developing new products which extend power reserve duration to 72 hours.

The 3D laser mapping technique produces 97% visual similarity in appearance components but the heat treatment process along with assembly precision requires the use of 60% original movement bearings in 1:1 clone products.

From an ethical perspective of technology we support the "craft tribute" method which uses classic design engineering knowledge to develop new materials-based innovative approaches. The designers reconstructed the vintage diving watch structure from the 1960s using grade 5 titanium alloy with 4.5g/cm3 density which both preserves the aesthetic characteristics while delivering a 30% weight reduction.

Conclusion

The watchmaking industry demonstrates precision mechanical engineering excellence while sustaining an endless contest between artistic beauty and industrial efficiency. The real technological transformation during industrialization 4.0 requires more than basic classic duplication because it depends on mechanical watchmaking principles that merge with technological advancements.